Product Feature:

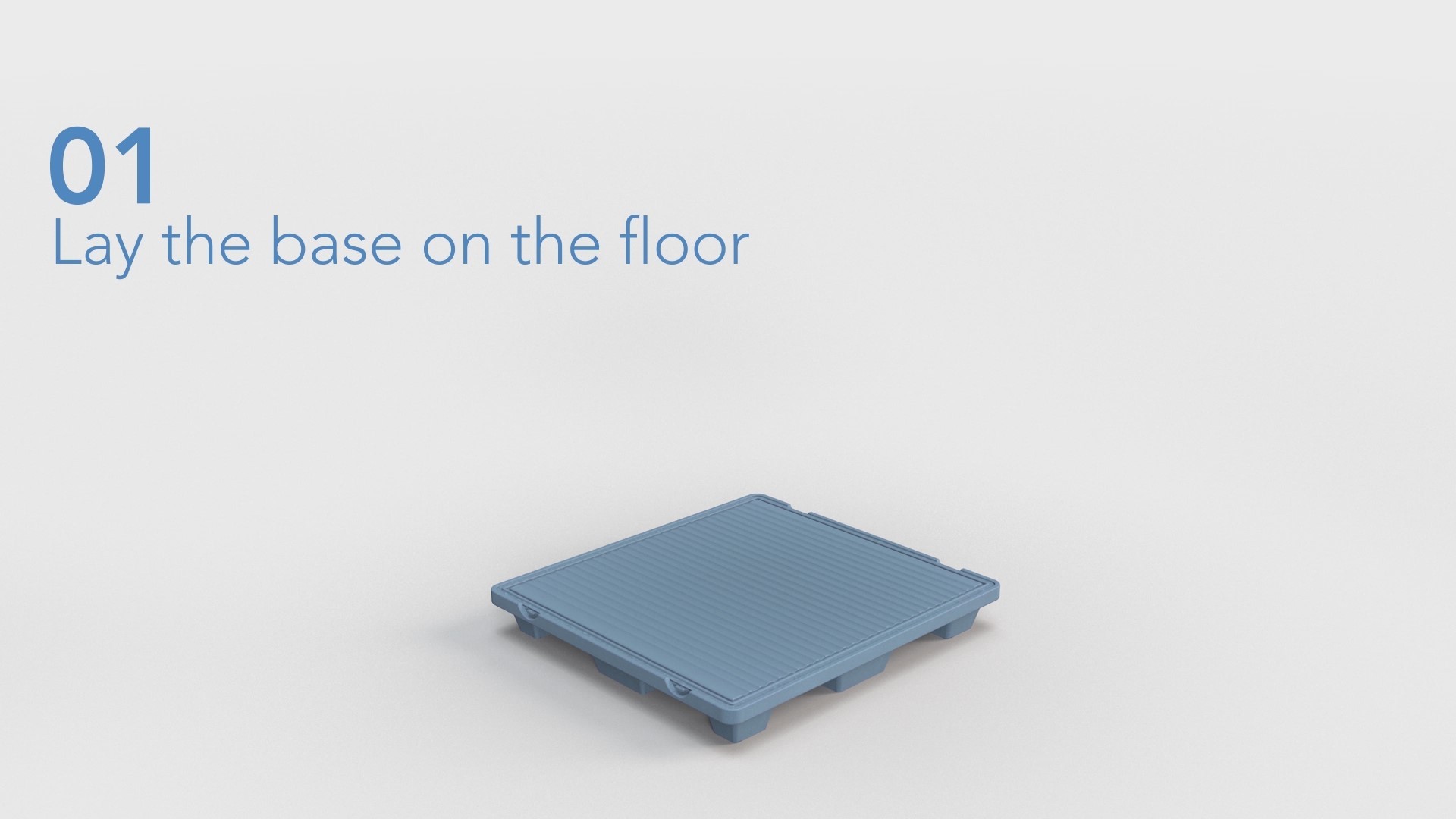

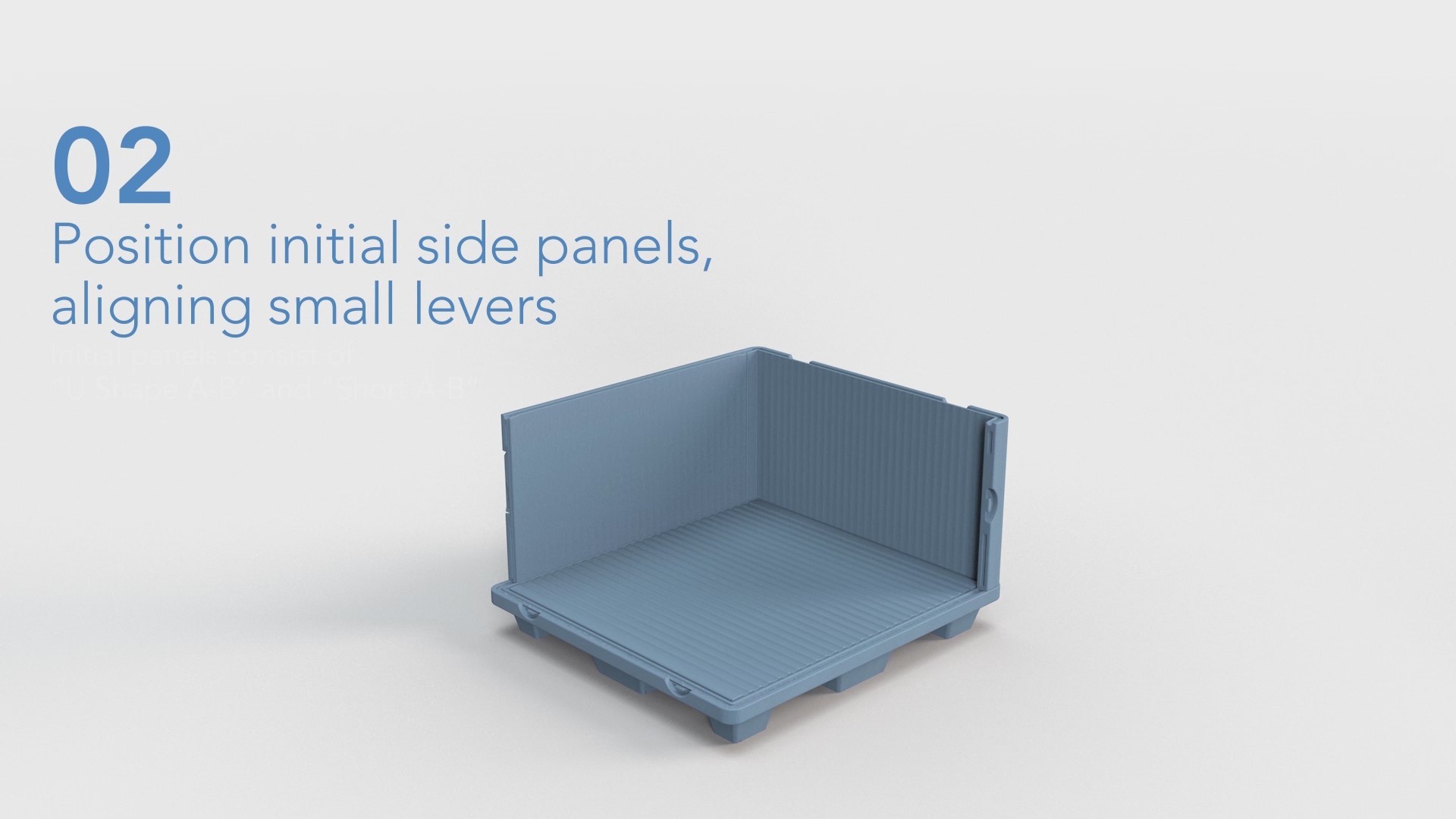

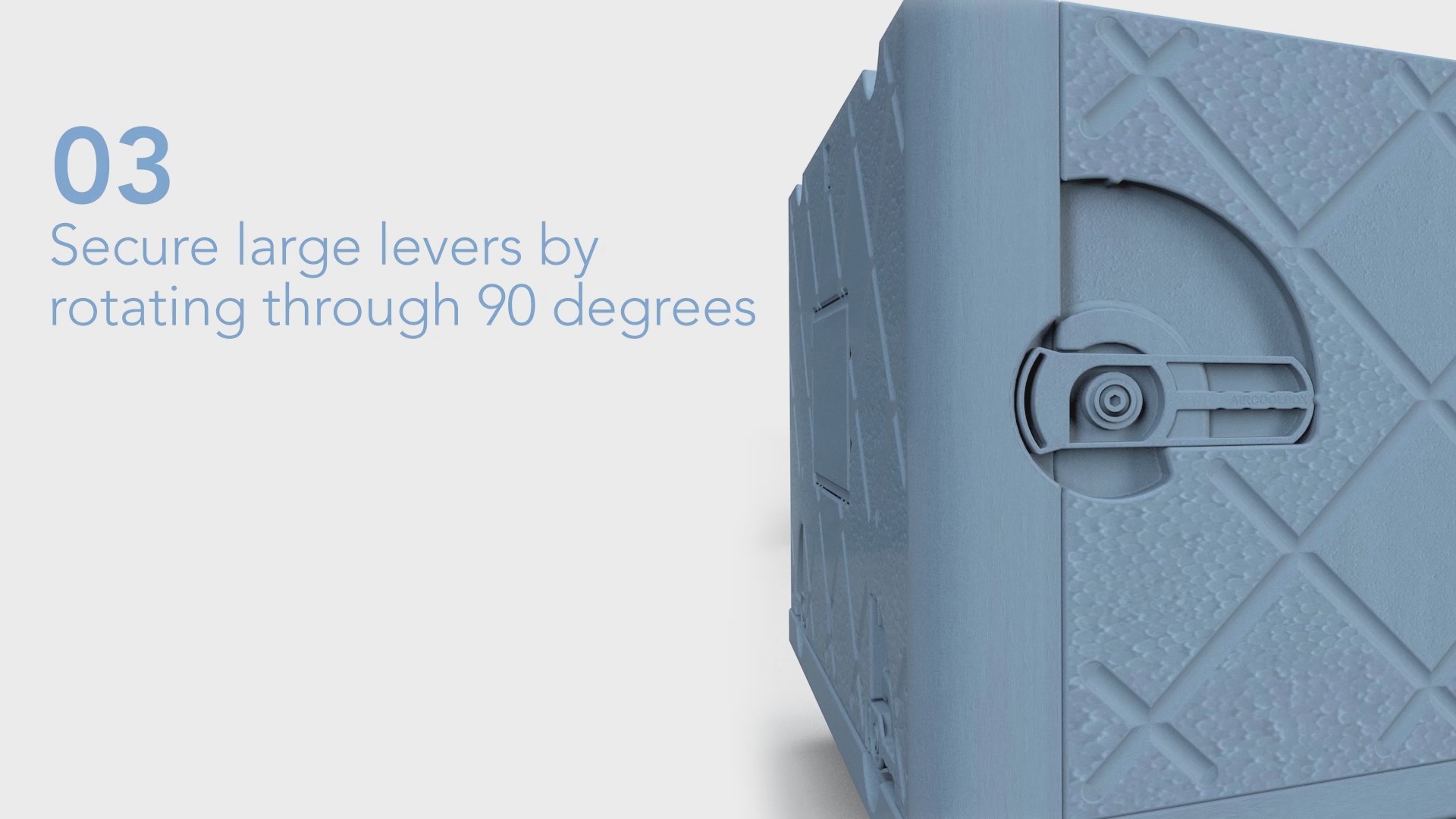

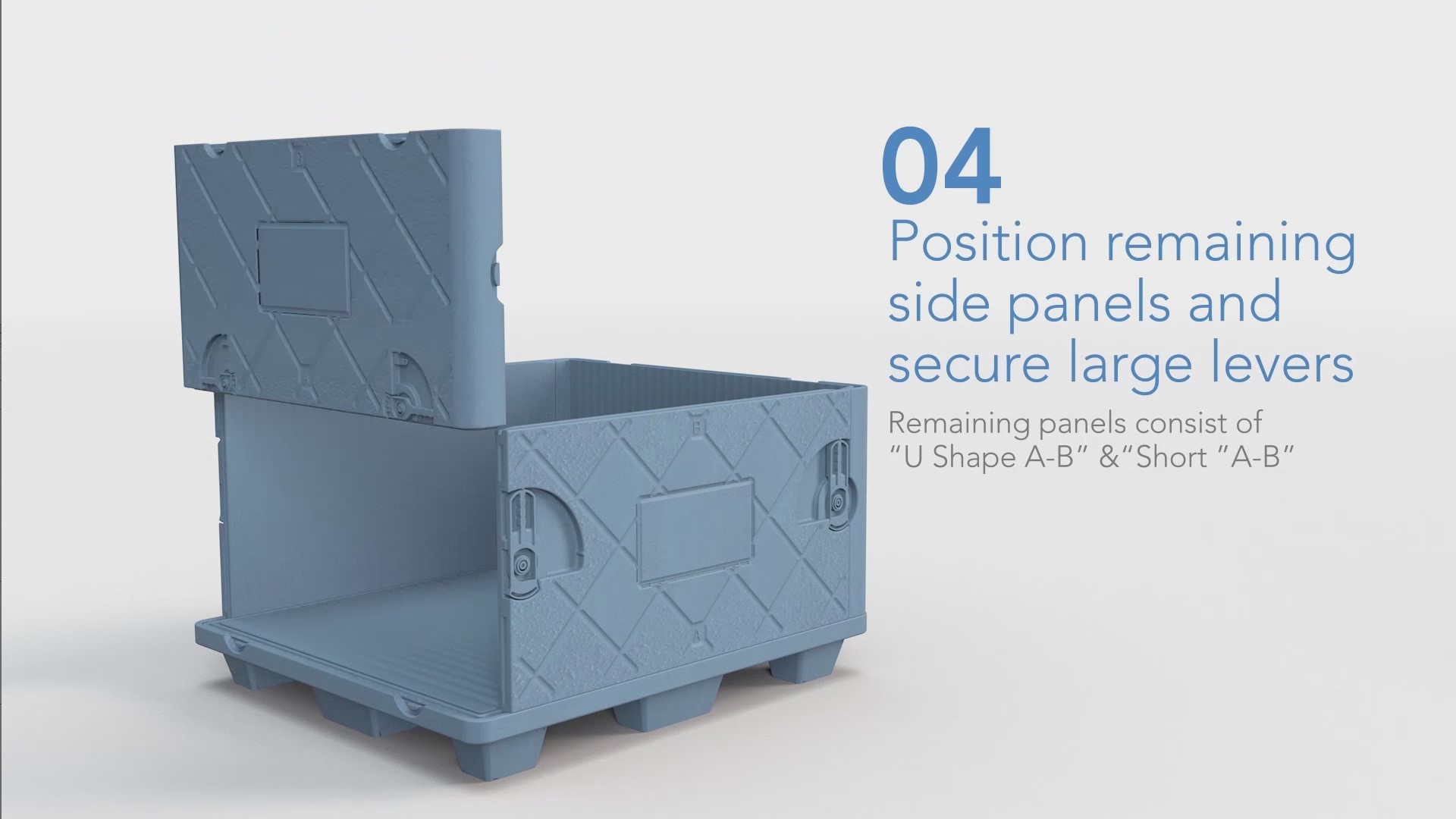

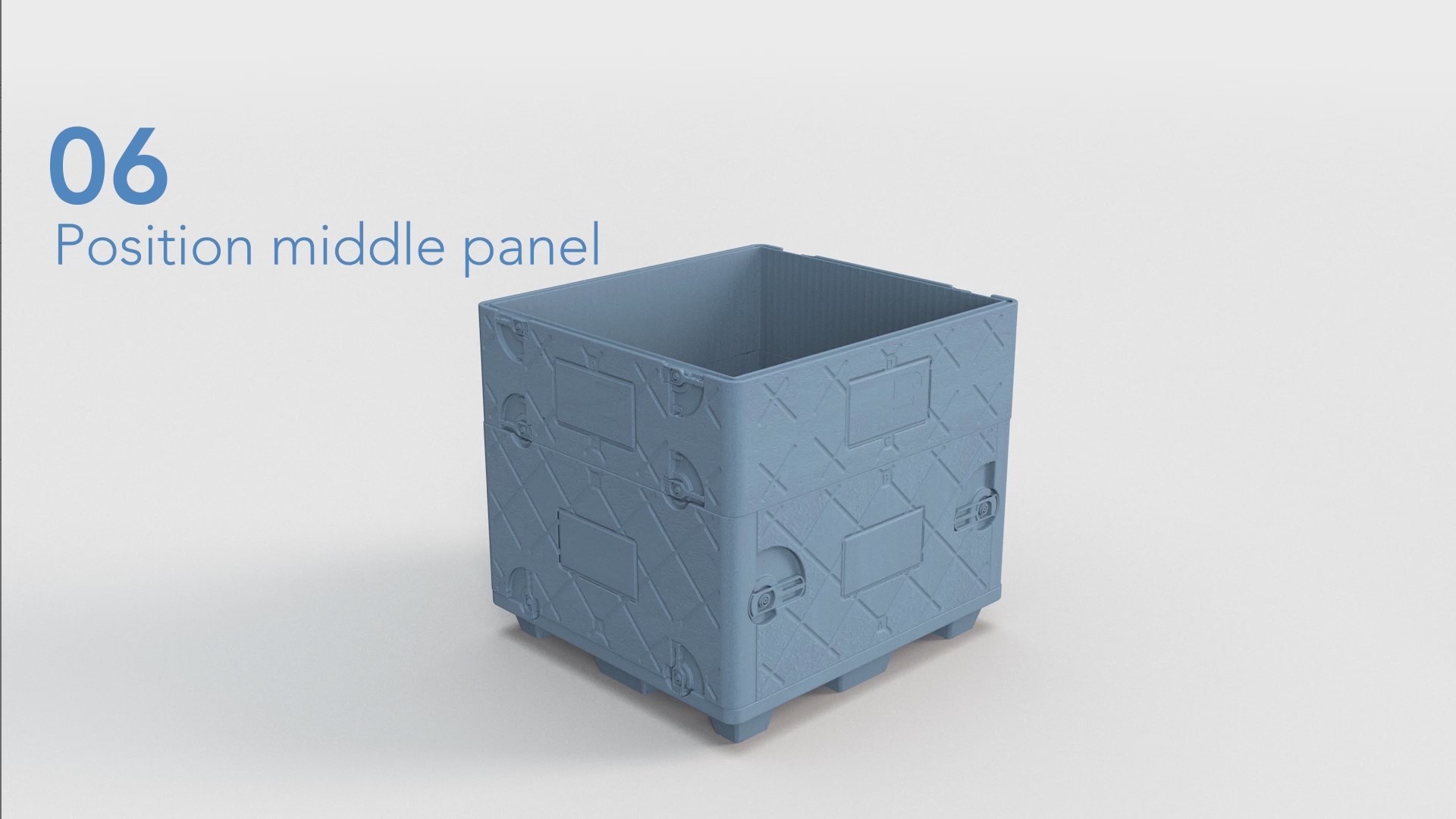

1. Unique design: 123coolbox uses a self-aligning feature that's built into the panels. A unique, one-handed operation "locking lever" secures each panel layer to each other, whilst a simple lever operation and latch mechanism, fixed and flush to the panels, secures the whole assembly as a one piece unit. The unit flat-packs into itself as the side panels fit inside the one piece mid-panel between the base and lid.

2. Customization: For larger orders, the 123coolbox can be customized with the customers colour choice, and they can easily include corporate identities, logos and branding

3. Insulating materials: The 123coolbox is an insulated, collapsible container that protects products and keeps them within a temperature range of +2℃ to +8℃ and +15℃ to 25℃ without additional refrigerant for up to 120 hours.

4. Easy to use: 123coolbox is easy to build and designed to optimise sapce. They can be flat-packed and made available as required, with no specialist airfreight requirements. With a modular design and few interchangeable parts. 123coolbox includes an integral pallet base which makes it easier to move by pallet jack and forklift.

5. Better than throwaway packaging: Throwaway packaging are bulky and easily damaged, and dry ice and gel packs add weight to shipments and increase airfreight cost. 123coolbox's solution reduces wastage and ensures an environmentally-friendly approach to packaging and distribution. Delays in transit usually require new dry ice and gel packs, whilst polystyrene attracts a disposal tax in Europe; 123coolbox sidesteps these problems by avoiding environmentally-damaging materials.